Precise viscosity control is crucial in a wide range of industries, from pharmaceuticals to food, petrochemicals, and cosmetics. Viscometers have been essential tools to ensure that products maintain their quality, consistency, and safety.

In this article, we will focus on the importance of viscometers, specifically those from the Kalstein brand, their features, models, and how they compare to other similar products on the market.

If you are looking for a fusion of innovation and quality, you’ve come to the right place. At https://kalstein.pt/category-product/laboratory-line/viscometer/, we offer the luxury of exploring our exclusive laboratory equipment catalog. We manufacture each piece of equipment with a high level of excellence. Our intuitive and agile online purchasing channels are designed for your convenience, ensuring the most competitive prices. Don’t hesitate any longer; we bring science to life, and it’s time to become part of our community. https://kalstein.pt/

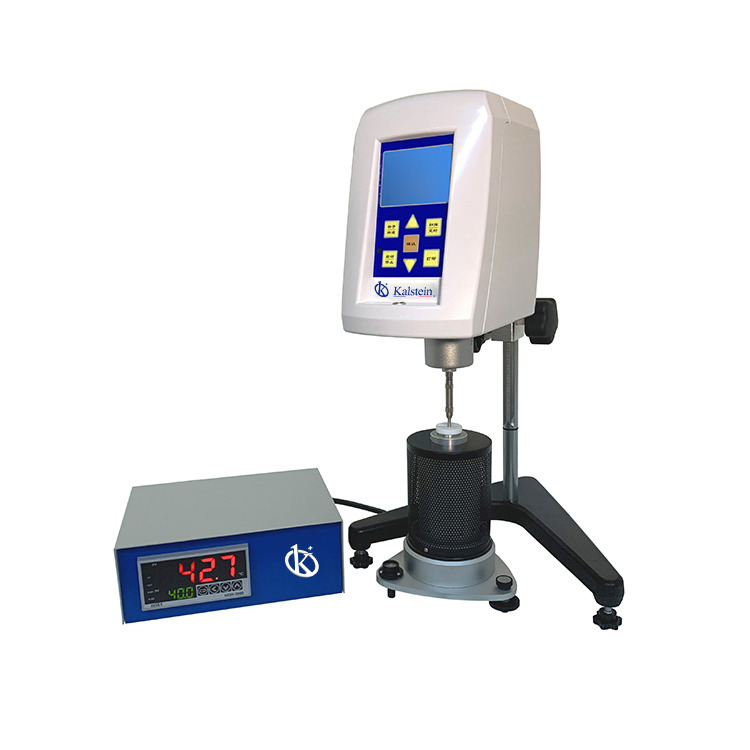

Viscometer, Kalstein Brand

As someone who has had the opportunity to test several solutions for measuring viscosity, I can say that Kalstein’s viscometers stand out for their precision and reliability. The brand has earned recognition in the industry for its dedication to innovation and quality. Kalstein viscometers are designed with modern laboratories in mind, which require consistent and reliable testing for their products.

One reason why Kalstein’s equipment is so highly regarded is its ease of use and advanced technology. These viscometers not only measure viscosity accurately, but also offer intuitive tools that make operation easier, making them a popular choice in both research laboratories and industrial environments.

Features of the Viscometer

The viscometer is equipped with several features that make it stand out. Among the most notable are its ability to measure both low and high viscosity fluids with exceptional precision. Additionally, these viscometers provide quick results, reducing testing time, which is a significant benefit in work environments where efficiency is key.

Another important feature is its durability. These devices are designed to withstand continuous use in laboratories and industrial plants without losing precision over time. The integration of digital systems that allow real-time data visualization and connectivity with other devices is also a differentiating factor that Kalstein has effectively implemented in its products.

Different Types or Models of the Viscometer

Within the range of viscometers, Kalstein offers several models that cater to the specific needs of each industry. There are rotational viscometers, which are perfect for measuring non-Newtonian liquids, and capillary viscometers, which are ideal for low-viscosity liquids. Depending on the application, whether for pharmaceuticals, paints, or food products, Kalstein has a solution that meets the process requirements.

Rotational models, for instance, allow viscosity to be measured under different shear conditions, which is essential for materials that change their behavior under stress. Meanwhile, capillary viscometers offer precise and repeatable measurements for homogeneous liquids. This diversity of options enables laboratories to choose the right equipment according to their specific needs.

Why Does the Viscometer Have This Price?

The price of a high-quality viscometer like those offered by Kalstein is justified for several reasons. First, the precision and reliability that these devices provide are unparalleled in the market. Measuring viscosity accurately can prevent costly errors in production and ensure the quality of the final product.

Moreover, the viscometers are constructed with highly durable materials and feature state-of-the-art technology. This ensures that the equipment not only delivers accurate results but also has a long lifespan, which in the long run represents a cost-effective investment for any laboratory or industrial plant.

Compare the Viscometer with Similar Products

When comparing Kalstein’s viscometers with other similar products on the market, such as those from Brookfield, Anton Paar, and Fungilab, several significant differences can be noted.

-

Brookfield: A well-known brand with a wide range of viscometers, but its models are often more expensive compared to Kalstein, without offering significant improvements in precision or ease of use.

-

Anton Paar: Their viscometers are primarily aimed at high-level research laboratories, and although extremely precise, they tend to be less accessible in terms of cost and technical requirements compared to Kalstein.

-

Fungilab: Offers good quality products, but lacks the robustness and durability that Kalstein guarantees. Additionally, Fungilab’s viscometer user interface is not as intuitive, which can complicate its use in industrial environments.

In summary, Kalstein’s viscometers offer excellent value for money, without sacrificing precision or durability, making them a preferred choice in both small laboratories and large industrial facilities.

Pros and Cons of the Viscometer

|

Pros |

Cons |

|

High precision in measurement |

Can be expensive for small laboratories |

|

Versatile models for various applications |

Requires regular maintenance |

|

Easy to use |

Initial training needed for optimization |

|

High-quality and durable materials |

Some models can be bulky |

|

Digital connectivity for real-time analysis |

|

|

Fast and efficient results |

|

|

Wide range of models for specific needs |

|

|

Excellent value for money |

Benefits of Using These Viscometers

The benefits of using a Kalstein viscometer are numerous. In addition to the aforementioned precision and reliability, these devices help optimize production processes. By accurately measuring viscosity, it ensures that final products meet quality standards, reducing rejections and reworks.

Another important advantage is the reduction of long-term operational costs. As robust and durable equipment, these viscometers require fewer repairs and maintenance than other models on the market, representing a significant saving over the equipment’s lifecycle.

Other Advantages of the Viscometers

Besides the previously mentioned benefits, Kalstein viscometers are easy to integrate into automated systems, facilitating their use in production lines where continuous viscosity control is essential. They also stand out for their ability to handle a wide range of viscosities, making them a versatile tool in various industries.

The technical support offered by Kalstein is another strong point. The company has a team of experts available to resolve any questions or problems that may arise during the installation or use of the equipment, ensuring high-quality after-sales service.

User Reviews of the Viscometers

Many users from different industries have expressed their satisfaction with Kalstein’s viscometers. Pharmaceutical laboratories, for example, have highlighted the precision of these devices in ensuring that their formulations meet the viscosity standards required for regulatory approval.

In contrast, companies in the food sector have mentioned the reliability of the equipment in maintaining product consistency, leading to greater customer satisfaction.

Frequently Asked Questions

How do I choose the right viscometer for my application?

It depends on the type of liquid you are measuring. If you work with non-Newtonian fluids, a rotational viscometer will be your best option. For low-viscosity liquids, a capillary viscometer may be more appropriate.

What viscosity range can viscometers measure?

Viscometers are designed to measure from very low viscosity liquids to highly viscous materials, making them versatile for a variety of applications.

Is it difficult to use a viscometer?

No, viscometers are designed to be easy to use, even for users without much technical experience. The interface is intuitive and allows precise results with minimal effort.

How much maintenance does a viscometer require?

These viscometers are built with high-quality materials, reducing the frequency of maintenance. However, periodic cleaning and annual calibration are recommended to ensure optimal performance.

What sets Kalstein viscometers apart from similar products?

The combination of precision, durability, and ease of use, along with excellent after-sales service, makes Kalstein viscometers a very attractive option compared to other brands.

Can I integrate a viscometer into my automated system?

Yes, many models are ready for integration with automated systems, facilitating their use in production lines.

Final Recommendations on These Viscometers

In summary, Kalstein’s viscometers are a smart investment for any laboratory or industrial plant seeking precision, reliability, and ease of use in viscosity control. These viscometers are indispensable tools for controlling viscosity in various industrial and laboratory environments. Their combination of precision, durability, and ease of use sets them apart in the market, offering effective solutions to guarantee the quality and consistency of products.

The variety of available models allows users to select the most suitable equipment according to their specific needs, from low-viscosity liquids to denser materials. Additionally, the integration of advanced technology and the ability to connect these devices to automated systems further optimizes production processes.